Re: Worm gears

Posted: Sun Dec 13, 2015 12:29 pm

Art

Pinion I feel would be easy, it's a low helix gear with an additional z axis move in the centre.

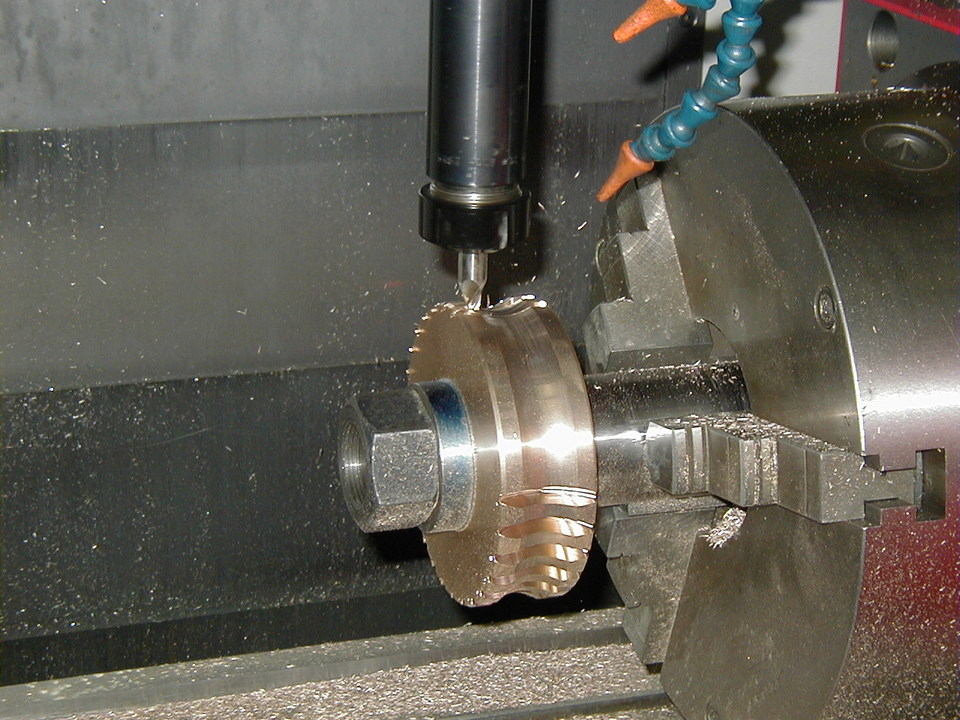

I'll include this picture stolen without credits from Bob Whorefields site as he steals everything and credits no one ;D

It would be easier using a vee cutter and as most pinions / wheels are done in a soft material i single flute cutter similar to an engraving cutter could be used. After all the most common angles would be 20 and 29 degrees or 30 for the trapezoidal guys in EU land.

Worms them selves are just screws so using anything other than a lathe is just an exercise in getting a good spanking [ mind you that's not bad at the right hands :o ]

If you were serious though it's simple job to hand write a code and mill one with the exact same cutter, or Gearotic could even spit the code out given you fill a few boxes in.

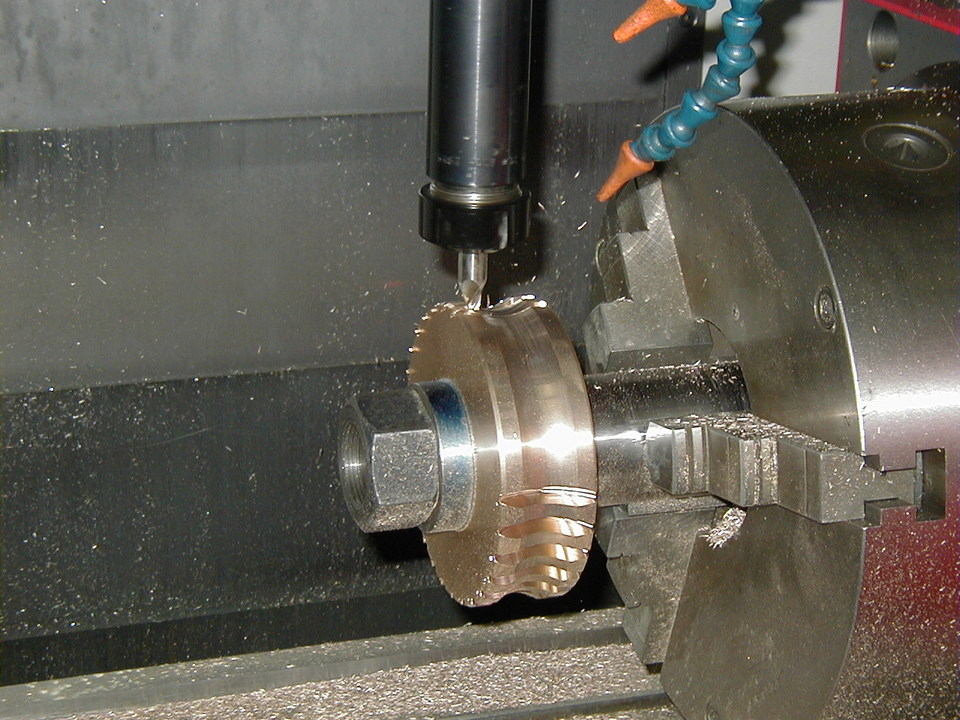

This was just a test once to see how easy iy would be to do a square thread.

Pinion I feel would be easy, it's a low helix gear with an additional z axis move in the centre.

I'll include this picture stolen without credits from Bob Whorefields site as he steals everything and credits no one ;D

It would be easier using a vee cutter and as most pinions / wheels are done in a soft material i single flute cutter similar to an engraving cutter could be used. After all the most common angles would be 20 and 29 degrees or 30 for the trapezoidal guys in EU land.

Worms them selves are just screws so using anything other than a lathe is just an exercise in getting a good spanking [ mind you that's not bad at the right hands :o ]

If you were serious though it's simple job to hand write a code and mill one with the exact same cutter, or Gearotic could even spit the code out given you fill a few boxes in.

This was just a test once to see how easy iy would be to do a square thread.